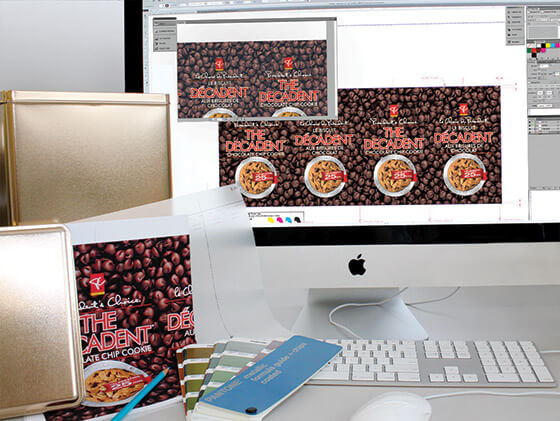

Raw Materials and Resources

Our strategic purchases of raw materials such as steel, enables us to provide high quality products to our customers without interruption. Our financial stability and reputation make us an attractive customer to steel mills, ink and coating manufactures and other suppliers. We source globally and forecasting our needs. This protects our customers from market volatility and supply disruption. We have strategically located printing facilities; one on the East Coast and the second in the Midwest. We have more capacity and capability to produce and deliver lithographed tinplate than any company in America.